"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

12/17/2018 at 11:49 ē Filed to: None

2

2

6

6

"Duck Duck Grey Duck FTMFW!" (theduckduck)

"Duck Duck Grey Duck FTMFW!" (theduckduck)

12/17/2018 at 11:49 ē Filed to: None |  2 2

|  6 6 |

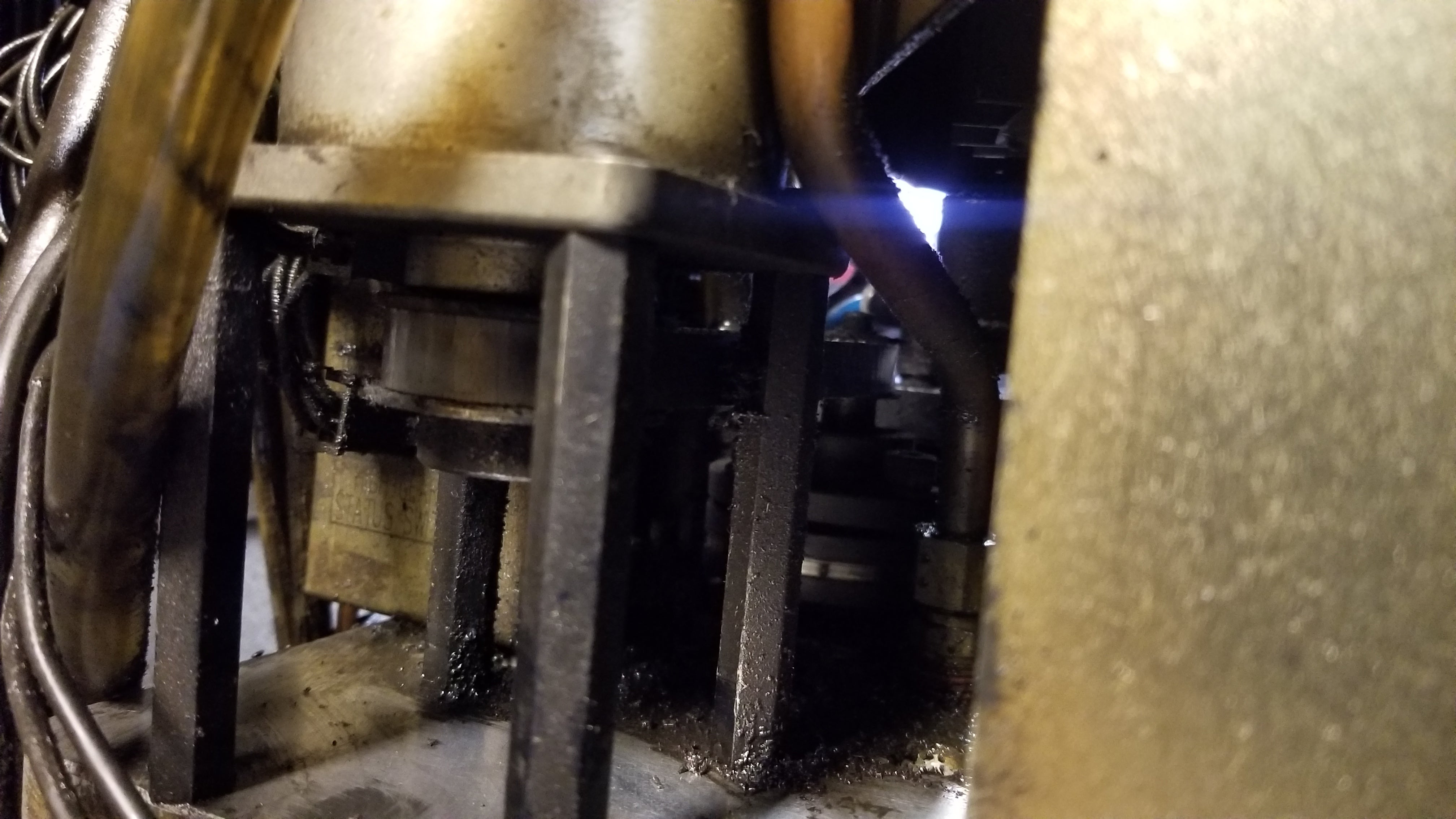

Last Friday we finally decided to fix my Haas VF-3 Mill. It had been tappi ng very poorly and it turned it was because of this tiny belt that was 30 years old! The belt itself was very cracked and had completely worn out the driven gear. This little belt runs an encoder which needs to sync up with the Z axis so it can feed in and out of the part without destroying everything. There was so much slack in the belt that it was cutting on the way into the part AND out. It now taps like a brand new machine.

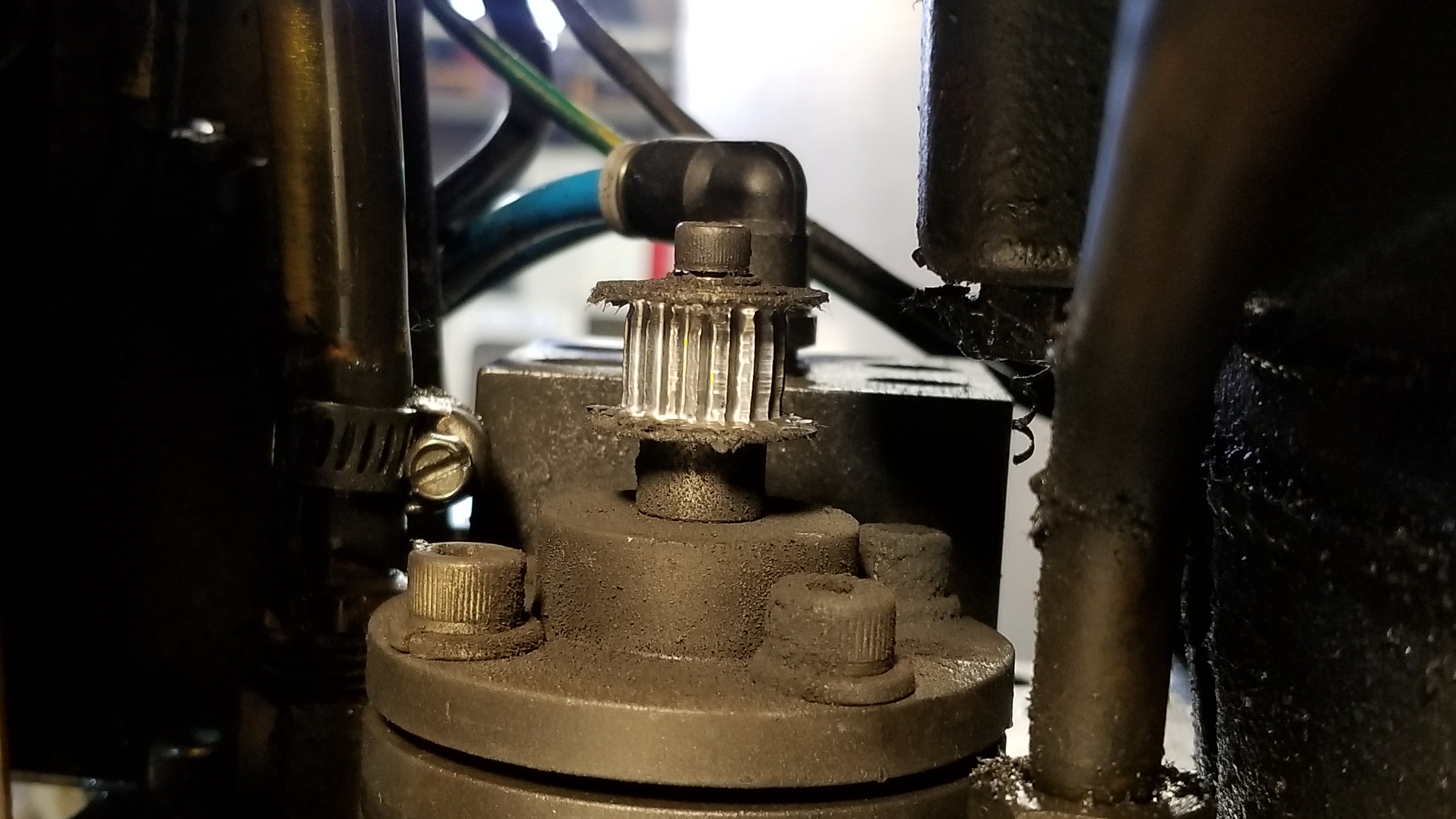

The thing in the black posts is the encoder.

This part spins together with the spindle and drives the encoder.

!!!CAPTION ERROR: MAY BE MULTI-LINE OR CONTAIN LINK!!!

!!!CAPTION ERROR: MAY BE MULTI-LINE OR CONTAIN LINK!!!

bob and john

> Duck Duck Grey Duck FTMFW!

bob and john

> Duck Duck Grey Duck FTMFW!

12/17/2018 at 14:29 |

|

wow. Iím SH OC KED the belt didnt give before the metal

MM54

> Duck Duck Grey Duck FTMFW!

MM54

> Duck Duck Grey Duck FTMFW!

12/17/2018 at 17:36 |

|

Wait, you have a VF3?

Duck Duck Grey Duck FTMFW!

> MM54

Duck Duck Grey Duck FTMFW!

> MM54

12/18/2018 at 09:37 |

|

Yessir!!! Why do you ask?

Duck Duck Grey Duck FTMFW!

> bob and john

Duck Duck Grey Duck FTMFW!

> bob and john

12/18/2018 at 09:38 |

|

I was too. It was still plenty strong too. I gave it †a tug and no breakage.

MM54

> Duck Duck Grey Duck FTMFW!

MM54

> Duck Duck Grey Duck FTMFW!

12/18/2018 at 18:01 |

|

Thatís really really cool.

Duck Duck Grey Duck FTMFW!

> MM54

Duck Duck Grey Duck FTMFW!

> MM54

12/19/2018 at 15:45 |

|

It is pretty cool. I wish my company did cool stuff with it. I do on my own time but on the job stuff is mind †numbingly boring.